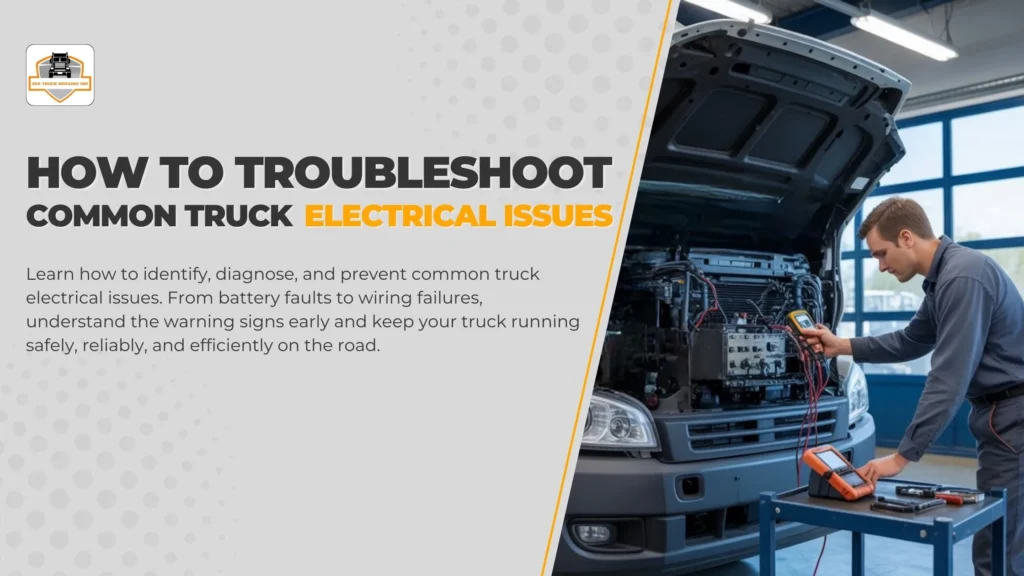

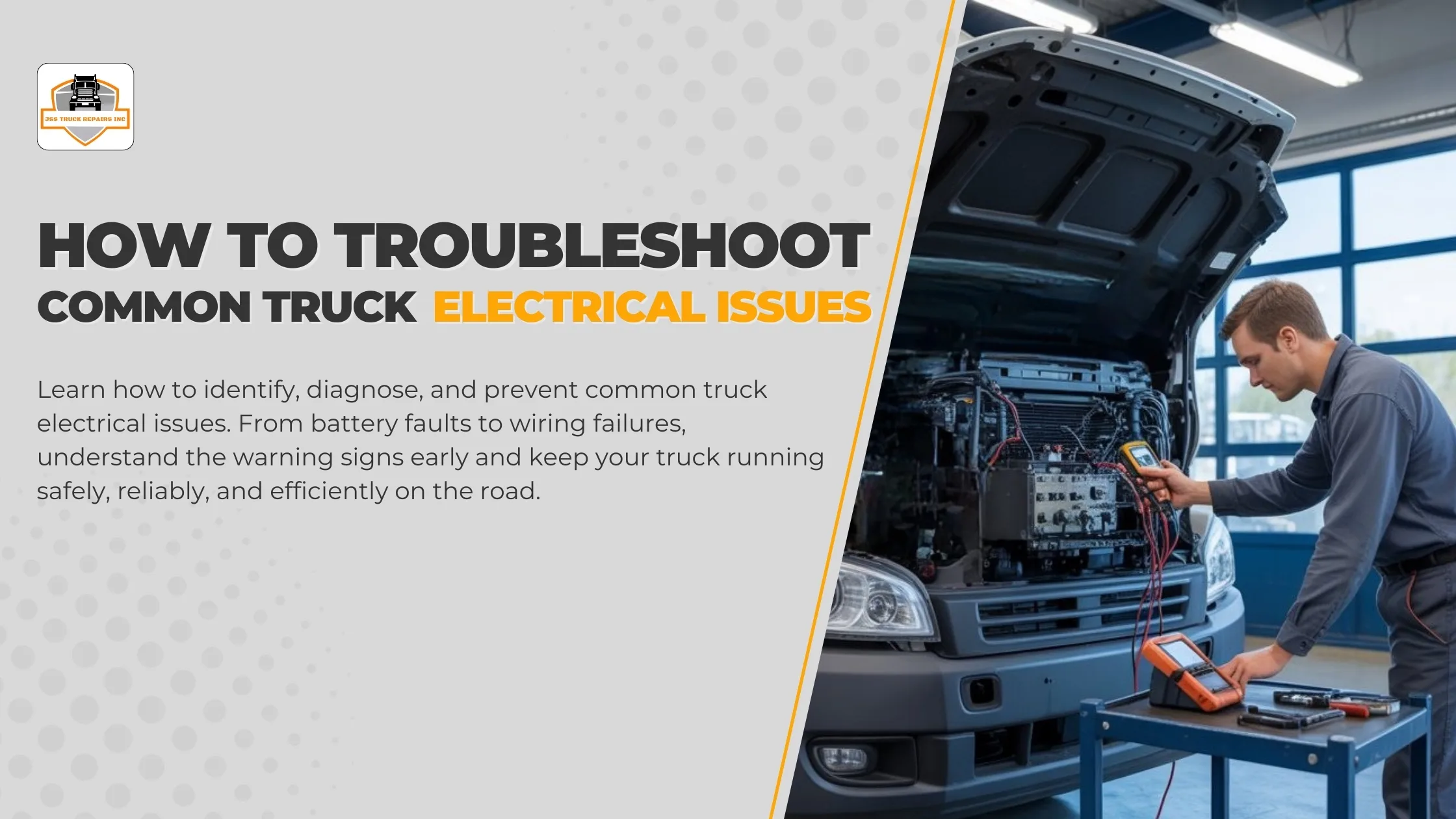

Truck electrical systems are becoming more advanced every year, but that also means electrical problems can show up more frequently and cause unexpected downtime. Whether it’s dim headlights, a non-responsive starter, or warning lights flashing on your dashboard, truck electrical issues can quickly affect performance, safety, and your ability to stay on the road.

Understanding the basics of electrical troubleshooting can help drivers and fleet owners identify early warning signs, prevent breakdowns, and decide when professional help is needed. In this guide, we’ll break down how to troubleshoot common truck electrical issues, the symptoms to watch for, and the steps you can take before visiting a certified technician.

If you’re maintaining your vehicle regularly or searching for a reliable Truck Repair Service in Etobicoke, learning how to identify electrical faults is the first step toward keeping your truck running safely and smoothly.

Why Truck Electrical Issues Should Never Be Ignored

Modern trucks depend heavily on electrical systems—everything from ignition and lighting to sensors, control modules, and battery-powered components. When these systems fail, the impact is almost immediate.

Ignoring electrical problems can lead to:

- Sudden breakdowns

- Damage to expensive components

- Loss of power steering or braking support

- Safety hazards while driving

- Increased repair costs

Even during a routine visit to the JSS Truck Repairs Inc workshop (as drivers discover from the homepage), many hidden electrical faults can surface long before they become severe.

This is why early troubleshooting is essential.

1. Recognizing Signs of Electrical Failure in Trucks

One of the most important skills a driver can develop is identifying signs of electrical failure in trucks before they turn into large repairs. These issues tend to show up gradually but worsen quickly if ignored.

Here are some early indicators:

✔ Dim or flickering headlights

This usually suggests a failing alternator, weak battery, or loose wiring.

✔ Dashboard warning lights

Electrical faults often cause ABS, airbag, or battery indicators to illuminate unexpectedly.

✔ Difficulty starting the engine

A slow or weak crank is a classic sign of deeper truck electrical issues.

✔ Strange electrical behavior

This could include power windows moving slowly, interior lights flickering, or random beeps.

✔ Burning smell near fuse box or wiring

This is a serious warning sign and requires immediate inspection.

If any of these symptoms appear repeatedly, it’s time to take a closer look.

2. Troubleshooting Truck Battery Problems

Your truck’s battery is the first point of contact when diagnosing electrical problems. Many truck battery problems stem from simple issues that drivers can easily check.

Step-by-step battery troubleshooting:

✔ Check for corrosion

Corroded terminals block electrical flow. Cleaning them can instantly improve performance.

✔ Test battery voltage

A fully charged battery should read around 12.6 volts. Anything below 12.2 indicates weakness.

✔ Inspect battery cables

Loose or damaged cables can mimic a dead battery.

✔ Consider battery age

Most truck batteries last 3–5 years. Anything older may no longer hold charge effectively.

When voltage repeatedly drops despite proper charging, this usually signals deeper truck electrical issues connected to the alternator or wiring.

3. Understanding Faulty Truck Alternator Symptoms

The alternator keeps your truck battery charged while driving. When it starts failing, electrical problems spread across the entire truck.

Signs of a failing alternator:

- Engine stalling while driving

- Battery warning light turning on

- Headlights dimming when idling

- Burning smell near the engine

- Clicking or whining noises

If the alternator output is lower than required, the truck will rely solely on battery power — which can drain it quickly.

A weak alternator is one of the most common truck electrical issues, and ignoring it can leave you stranded unexpectedly.

4. Checking Truck Fuse and Wiring Issues

Faulty fuses and wiring can cause power failures, lighting issues, and intermittent functions throughout the truck. They’re also one of the most difficult problems to detect without experience.

Common wiring and fuse issues include:

- Blown fuses

- Brittle or cracked wires

- Poor grounding

- Melted insulation

- Loose connectors

Basic troubleshooting steps:

✔ Inspect the fuse box

Replace blown fuses with ones of the same amperage rating only.

✔ Check wiring harnesses

Look for discolouration, exposed copper, or heat damage.

✔ Test continuity

This helps confirm whether a wire is broken internally.

Electrical wiring problems are among the trickiest truck electrical issues because they may not show up consistently. If you notice electrical components working one day and failing the next, wiring is a likely culprit.

5. How to Diagnose Truck Electrical Faults (Step-by-Step)

Diagnosing electrical issues requires patience and a systematic approach.

Here’s a simplified step-by-step method:

1. Start with the symptoms

Whether it’s dim lights or a weak crank, always begin with what you observe.

2. Check voltage at the battery

This confirms whether the problem is battery-related.

3. Inspect alternator output

A properly functioning alternator should produce above 13.5 volts while running.

4. Test the starter motor

If the truck struggles to start, the starter might be drawing excessive current.

5. Inspect fuses and relays

Relays often fail silently, causing major electrical disruptions.

6. Look for loose connections

Vibration from long-distance driving often loosens terminals and grounds.

7. Scan for fault codes

Modern trucks store electrical error codes even when symptoms aren’t obvious.

This step-by-step method helps narrow down truck electrical issues without guesswork. However, for advanced diagnostics, using professional tools and experience becomes necessary.

When You Should Seek Professional Help

Not all electrical problems can be solved on the road. In cases such as:

- Repeated alternator failures

- Melted wiring

- Unresponsive ignition systems

- Dashboard electronics malfunctioning

- Sudden electrical shutdowns

…it’s safer to get professional diagnostics.

Drivers in the Etobicoke area who need reliable support often reach out through the JSS contact page to book inspections for ongoing electrical faults.

Electrical issues, if left unaddressed, can escalate into fire hazards or irreversible component damage.

Preventing Future Truck Electrical Issues

To reduce breakdowns and improve performance, regular electrical maintenance is essential.

Key preventive tips:

- Inspect battery terminals every month

- Avoid overloading electrical accessories

- Keep wiring protected from moisture

- Service alternator belts regularly

- Address dashboard warning lights immediately

Routine checks can help detect early truck electrical issues, saving time and avoiding costly repairs later.

Final Thoughts

Electrical problems are one of the leading causes of roadside breakdowns for commercial trucks. By recognizing early signs, understanding basic troubleshooting, and knowing when to call in experts, drivers can prevent major failures and keep their trucks running efficiently.

Whether you’re learning more about truck systems or searching for dependable Truck Repair Service in Etobicoke, staying informed is the best way to maintain safety and performance on the road.

If electrical symptoms persist or worsen, scheduling a professional inspection through the JSS contact page is always a smart move.